Decarbonize Process Heat—Profitably.

We make a new kind of industrial heat pump: 550 °C, plug-and-play, and smart enough to run only when electricity is clean and cheap. Your existing gas boiler handles the rest.

Industrial Heat Is Stuck on Fossil Fuels

Industrial processes need heat that's reliable and available 24/7. Gas boilers deliver this. While resistance heating can reach extreme temperatures, it's inefficient. Standard heat pumps are efficient but limited to 120-150°C. That's why 90% of industrial heat still comes from fossil fuels, even as electricity grids get cleaner. We built a system that uses both gas and electricity, choosing the cheaper, cleaner option in real-time.

The Industrial Heat Opportunity

Industrial process heat represents $1.2 trillion/year in global energy spend, with more than 3,000 TWh still served by fossil fuels in the 150–550°C range.

Electrifying even 10% of this would eliminate ~300 Mt of CO₂ annually—equal to the emissions of France.

Decarbonization Mandates Kick In This Decade

Thousands of industrial companies now have official CO₂ reduction targets. Most start hitting enforcement or compliance phases by 2030. That's why demand for decarbonized heat will surge this decade.

Source: SBTi, June 13, 2025

Cheap Electricity Is Hiding in Plain Sight

Electricity prices aren't just volatile—they're unequal. In every European market, there are thousands of hours each year when electricity is dramatically cheaper than average. This chart shows how many hours per year the price stays below a given threshold. In France in 2024, for example, power cost less than €50/MWh for nearly 4,000 hours—about 45% of the year.

If your system can shift demand into those hours, you save money. Most can't. Our hybrid heat pump can.

2024 EU Price Duration Curves

Why This Chart Matters

This price duration curve reveals how much hidden value exists in the power market. Our system unlocks that value—automatically switching between gas and electricity to cut costs and carbon, hour by hour.

Why most boilers can't respond — and ours can

Gas boilers can't participate in electricity markets or flexibility programs. They're stuck burning gas 24/7. But heat pumps can ramp up or down based on grid signals, capturing low prices and earning flexibility payments. That's why industrial users who shift from gas to electric heat pumps turn decarbonization into profit.

But capturing this opportunity requires a new kind of heat system—one that's cost-effective, dispatchable, and easy to deploy. That's exactly what we've built.

How It Works

We make a heat pump that reaches up to 550°C, delivered in shipping containers that connect to your steam network or heating equipment. The containers work alongside your existing gas boilers. When electricity is cheap and clean, the heat pump generates steam. When it's not, your gas boilers continue as normal. The system manages this automatically.

- Installs in a shipping container—no factory rework

- Connects directly to your steam lines

- Scales by adding containers as you expand electric capacity

The Airthium Heat Engine

Reaches up to 550°C—more than any other heat pump

Single-stage operation - no chained heat pumps needed

Non-toxic operation - unlike traditional heat pumps

Convert heat to electricity and back, ideal for thermal storage

With a fast near-isothermal heat transfer

Built for the Future

Our engine doesn't just electrify heat—it enables long-duration energy storage by converting between heat and electricity. Perfect fit for thermal batteries.

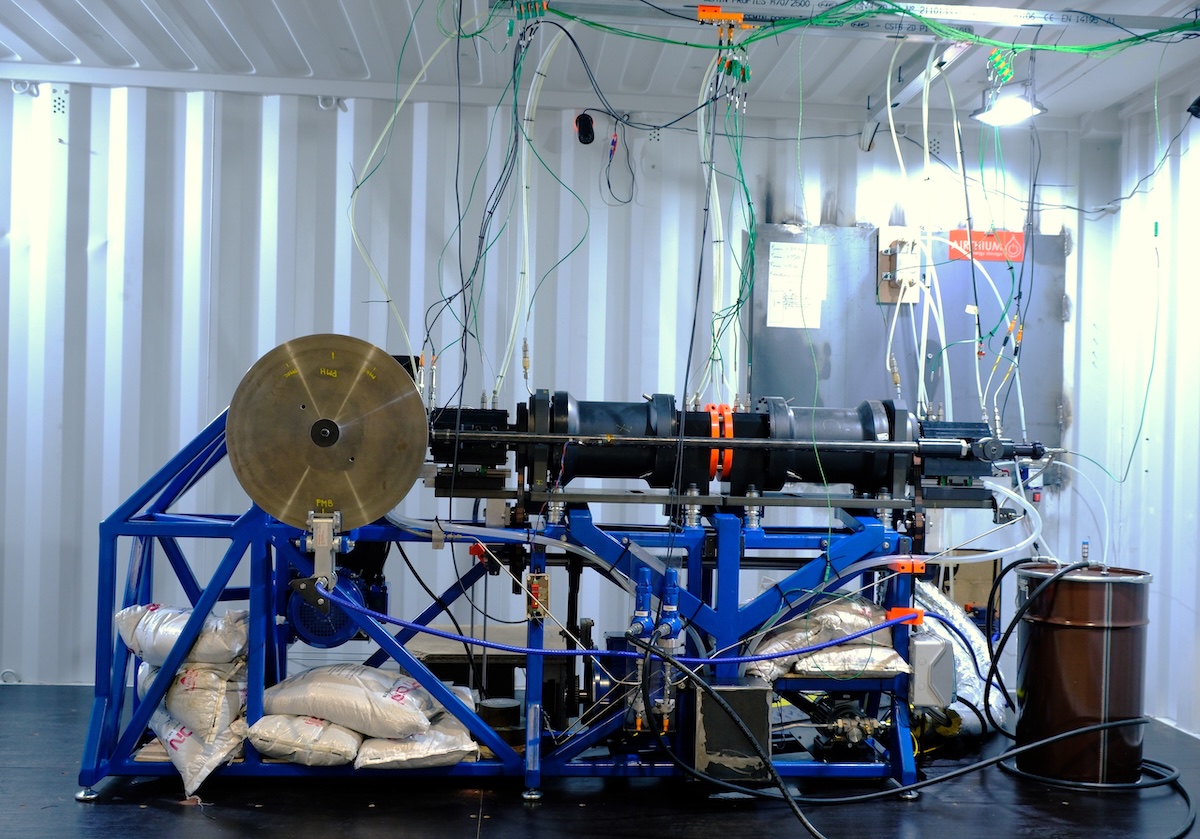

Our Heat Engine Prototype

Our prototype heat engine demonstrates the core technology that enables high-temperature heat pump operation. This compact unit is currently undergoing testing to validate performance and efficiency targets.

The Business Case

The upfront cost is higher than a gas boiler replacement—typically 2-3x. However, payback periods range from 3-7 years through three key value streams:

Lower Costs

Use electricity when it's cheap and gas when it's expensive

Hybrid operation means lower grid connection fees than pure electric boilers

Typical energy cost savings through smart switching and efficiency gains

Revenue Streams

Earn revenue by adjusting power use based on grid signals—turning decarbonization into profit.

€50-150/kW-yr for demand flexibility in many markets

EU carbon prices have climbed from €25/tCO₂ in 2020 to €85+ in 2024—and are projected to exceed €100 by 2030.

Every megawatt-hour of heat you shift from gas to electricity avoids emissions—and future penalties.

Enedis forecasts demand-side flexibility in France will grow from ~1 GW today to 6.5 GW in 2028 —opening up massive opportunity for smart, dispatchable heat solutions.

—Enedis Grid Flexibility Report(page 3)

Progress

We're currently building and testing a prototype that targets 200°C operation. The technology builds on proven Stirling engine principles but applies them in a new way to achieve higher temperatures than existing heat pumps. System efficiency will vary based on temperature lift and operating conditions - we're optimizing for real-world industrial applications.

World-Class Team

We've built a team of experts combining deep scientific knowledge with industrial expertise to solve one of the world's biggest climate challenges.

Leadership

Advisory Board

Get in Touch

If your site needs 150 – 300 °C steam and you’re exploring hybrid electrification, book a model run—we’ll create a tailored cost analysis for your specific site.

Prefer email? Reach us at: contact@airthium.com